Dairy Processing Equipment

Dairy Processing Equipment for Small & Medium Dairies

Tessa Dairy Machinery supplies durable, efficient dairy processing equipment for every stage of production — including pasteurizers, bottle and cup fillers, butter churns, and cream separators, all built to meet U.S. PMO standards.

Dairy Processing Equipment for Every Scale of Production

Tessa Dairy Machinery supplies reliable, efficient, and regulatory-compliant dairy processing equipment for milk, cream, butter, yogurt, and cheese production. Whether you're building a small creamery or scaling up industrial output, our equipment is engineered for consistent performance, U.S. PMO compliance, and long-term durability.

Our Equipment Categories

We offer a wide range of modular dairy processing machines, each available in multiple sizes and configurations:

Batch & HTST Pasteurizers

A dependable solution for pasteurizing milk in small and medium-sized dairy operations.

-

Processes 26 to 528 gallons (100–2,000 liters) per batch

-

Simple digital temperature control with built-in timer and safety alarms

-

Compatible with electric, gas, or steam heating systems

-

Fully stainless steel, insulated, and easy to clean

-

Complies with U.S. PMO standards for Grade A milk

-

Ideal for bottled milk, yogurt production, or cheese making

HTST Pasteurizers (High-Temperature Short-Time)

Designed for continuous milk pasteurization with fast processing, energy efficiency, and full regulatory compliance.

-

Flow rates from 132 to 2,641 gallons/hour (500 to 10,000 liters/hour)

-

Ideal for dairies that need consistent, high-throughput pasteurization

-

Includes balance tank, plate heat exchanger, holding tube, and flow diversion valve

-

Fully PMO-compliant for Grade A milk in the U.S.

-

Suitable for bottled milk, ESL milk, or large-scale yogurt production

-

Available with automatic or semi-automatic control panels

-

Compact footprint and easy integration into existing dairy lines

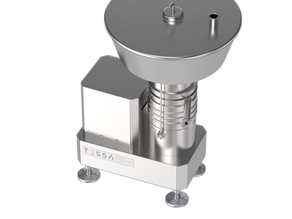

Cream Separators

Quick and reliable separation of cream from raw milk — built for daily use in dairies and creameries.

-

Processing capacity from 100 to 300 gallons/hour (379–1,136 liters/hour)

-

Built to 3A Sanitary Standards for food-grade safety in the U.S.

-

Fully CIP-ready design for easy cleaning

-

Adjustable cream and milk flow control for accurate fat standardization

-

Compact, stainless steel construction with low maintenance

-

Ideal for cream collection, butter production, or milk standardization

Butter Churns

Turn cream into high-quality butter with compact, easy-to-use churning machines — perfect for small creameries and farm dairies.

-

Batch sizes from 4 to 20 gallons (15 to 76 liters)

-

Reliable, smooth churning for consistent butter texture

-

Stainless steel drum and frame built for daily use

-

Includes discharge valve, drip tray, and inspection window

-

Fast cleaning and minimal maintenance

-

Suitable for sweet cream or cultured butter

Thinking About Starting To Process?

If you’ve been dreaming of processing your own milk — but didn’t know where to start or who to trust — we’re here for you. Whether you want to bottle your own milk, make yogurt, or start producing cheese, we’ll help you choose the right equipment and guide you through every step. At Tessa, we’ve worked with farmers, food entrepreneurs, and first-time producers all over the world. You don’t have to figure it out alone.

Milk Bottle Fillers

Reliable machines for filling plastic or glass bottles — available in manual, semi-automatic, and fully automatic models.

-

Fills 200 to 1,000 bottles per hour, depending on the model

-

Works with 1L, 500ml, 2L, and other standard bottle sizes

-

Options for manual, semi-automatic, or fully automatic operation

-

Built from food-grade stainless steel and designed to meet PMO standards

-

Add-ons available for capping, labeling, and date printing

-

Compact design fits small spaces and scales easily for larger operations

Cup Fillers

Compact and efficient machines for filling dairy products like yogurt, labneh, sour cream, and soft cheese into cups.

-

Fills 80ml to 500ml cups, depending on your product and packaging

-

Available in semi-automatic or fully automatic versions

-

Handles filling, sealing (with foil or plastic lids), and date printing

-

Built from stainless steel, easy to clean and maintain

-

Suitable for single-serve cups, food service portions, or larger formats

-

Optional add-ons: cup denester, lid dispenser, conveyor, and printer

-

Designed to fit easily into small and mid-sized production spaces

Pouch Filling Machine

Efficient filling systems for dairy products packaged in flexible bags — perfect for milk, yogurt, and ice cream mix.

-

Fills bags from 17 oz to 68 oz (500ml to 2L)

-

Ideal for stand-up pouches, bag-in-box, or pillow-style packs

-

Works with milk, yogurt, kefir, and similar liquid dairy products

-

Available in semi-automatic and automatic versions

-

Stainless steel construction with food-grade contact parts

-

Includes options for bag holders, sealing, and volume control

-

Great for retail pouches, institutional supply, or export packaging

Stainless Steel Tanks

Essential for every dairy plant — our tanks are built for hygiene, durability, and compliance with dairy regulations.

-

Capacities from 26 to 2,642 gallons (100 to 10,000 liters)

-

Used for milk storage, cream holding, mixing, aging, and blending

-

Made from 304 or 316 food-grade stainless steel

-

Fully welded, easy to clean, and built for long-term use

-

Available with insulation, jackets, agitation, and CIP-ready fittings

-

Designed to meet U.S. PMO and international sanitary standards

-

Custom sizes and configurations available to fit your dairy layout

Complete Dairy Solutions – Quality Equipment You Can Trust

At Tessa Dairy Machinery, we take pride in manufacturing high-quality, efficient, and reliable dairy processing equipment to support dairy producers worldwide. From pasteurization and cream separation to cheese pressing and packaging, our equipment is designed for efficiency, hygiene, and ease of use.

Whether you're a small-scale creamery or an industrial dairy plant, our innovative solutions help streamline operations and maintain the highest product quality standards.

Looking for the right equipment for your dairy production? Contact us today to discuss your needs and find the best solution for your business.